Program Overview

Pulsed Power

Serving large transient loads requires a power supply that can provide very high power and large scale energy storage. CEM has decades of experience in the design of high speed rotating electrical machines providing MW to GWs of power and and composite flywheels that store up to nearly 500 MJ (130kWhr) of energy.

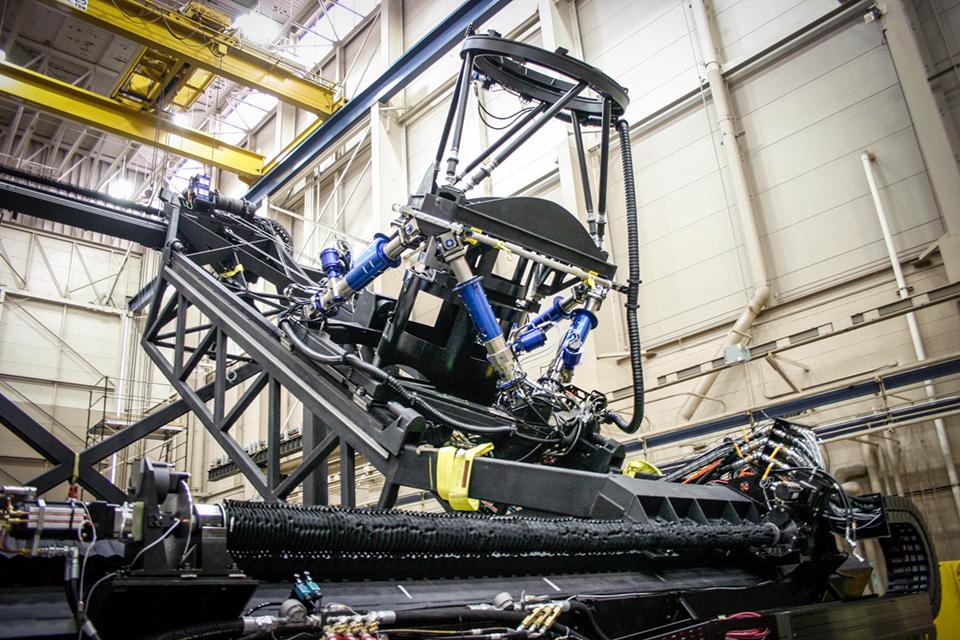

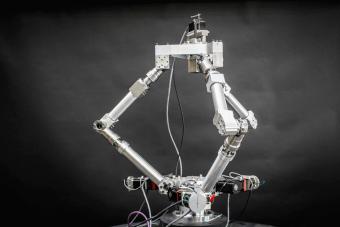

Space Research

CEM has conducted a wide variety of research for space applications including: Hobby-Eberly Telescope optical positioning system, Canfield Joint precision pointing system for satellite optical communication, and a flywheel design for the International Space Station. Other applications include: high temperature super conducting magnetic bearings for space flywheels, vibration Isolation for electronics racks on launch platforms, and an active suspension system for planetary rovers.

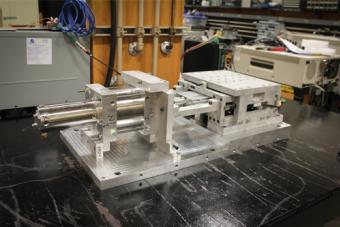

Linear Motors

Under CEM's Department of Energy ARPA-E award, CEM researchers leveraged expertise in modeling and controls to develop a free piston linear motor compressor with a single moving part (the free piston). As a result of this effort, CEM researchers reduced the cost of the compressor and qualified the dependency of the overall compressor efficiency on the physical attributes of the compressor and accuracy of the motor control systems.

CEM Approach

CEM engineers have access to a full suite of industry standard software and hardware including LMS Virtual.Lab, MATLAB, Solidworks, Maxwell 3D, Patran, ABAQUS, and many more. Initial system verification is typically done through simulation and the resulting control algorithm is then transferred into the lab and directly integrated into the testing environment. When warranted, CEM engineers develop custom algorithms or testing techniques appropriate to a unique application.

For more information please contact:

Scott Pish - Sr. Engineering Scientist

s.pish@cem.utexas.edu

512-232-1672