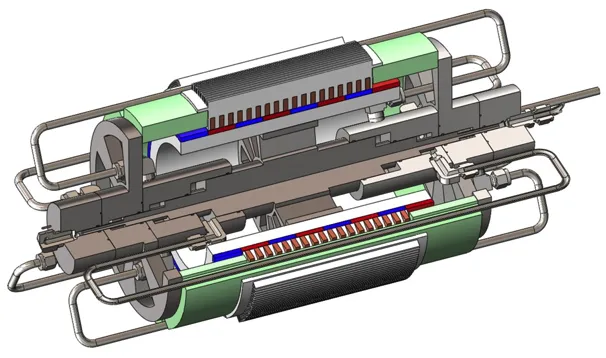

Under CEM's Department of Energy ARPA-E award, researchers were challenged to develop an in-home natural gas compressor that would last 3x as long, and cost 1/10th as much, as conventional residential natural gas fueling systems. To meet these objectives, CEM researchers invented a free piston linear motor compressor shown in Figure 1.

Figure 1. Linear Compressor Solid Model

This unique compressor design results in a single moving part (the free piston), thus reducing part count considerably when compared to rotary driven reciprocating compressors. With the team's aggressive compressor cost target of $500, it is critical that every element of the design be optimized for efficiency. Leveraging prior motor/generator design experience and tools, CEM performed a detailed linear motor trade study early in the project evaluating cost vs performance to identify the most efficient and suitable motor design for the compressor application.

CEM also leveraged experience in modeling and controls to develop dynamic simulations of the linear motor coupled to the reciprocating compressor. As a result of this effort, the CEM researchers were able to quantify the dependency of the overall compressor efficiency on several factors, such as physical attributes of the compressor and accuracy of the motor control systems. Understanding how each element of the design affects the compressor efficiency is critical in developing a compressor that allows for efficient residential natural gas vehicle refueling.

CEM has successfully completed fabrication and gas compression testing of the linear compressor design proving improved compressor life and durability. Current activities are focused on commercialization of the current concept design, as well as, leveraging this design to potentially provide motor solutions in other application fields.

Contact

Mr. Mike Lewis

mclewis@cem.utexas.edu

512-232-5715

Projects

H2@Scale

The Center for Electromechanics (CEM) through a Department of Energy (DOE) sponsored H2@Scale demonstration project – “Demonstration and Framework for H2@Scale in Texas and Beyond” – is developing a first-of-its-kind hydrogen technology proto-hub with multiple forms of renewable hydrogen generation and end users.

Linear Natural Gas Compressor

Program aims to engineer light-weight, affordable natural gas tanks for vehicles and develop natural gas compressors that can efficiently fuel a natural gas vehicle at home

Fuel Cell Hybrid Delivery Van

With a 150-mile range per fueling, this project will also retrofit 15 UPS delivery vans with fuel cell hybrid power trains and test these vehicles at distribution facilities.

Vibroseis Research

CEM advanced seismic exploration technology by developing a new EM transducer